Address:

Peuranoronkatu 5 37630 VALKEAKOSKI

tel. +358 40 506 2020

fax (03) 588 5017

valves.point@co.inet.fi

Our Full Overhaul

Valves are picked up from the customer for full overhaul. The overhaul starts with blasting the frame and parts with steel balls.

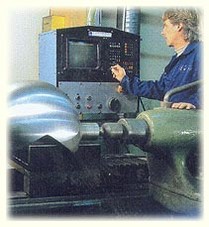

The balls and parts are machined according to their service needs. In this picture an DN 300 V-hole ball is being machined with CNC-controlled equipment.

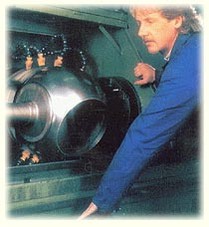

Ball valves are honed with special equipment. In this picture an DN 300 ball valve is being honed.

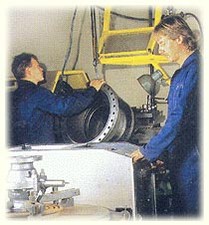

After machining, horning and replacement of service parts the valve is assembled. The fully overhauled valve is now as good as new.

All valves are checked and tested for pressure. Finally the valves are painted with corrosion-resistant primer and finished with top paint.

All valves are checked and tested for pressure. Finally the valves are painted with corrosion-resistant primer and finished with top paint.